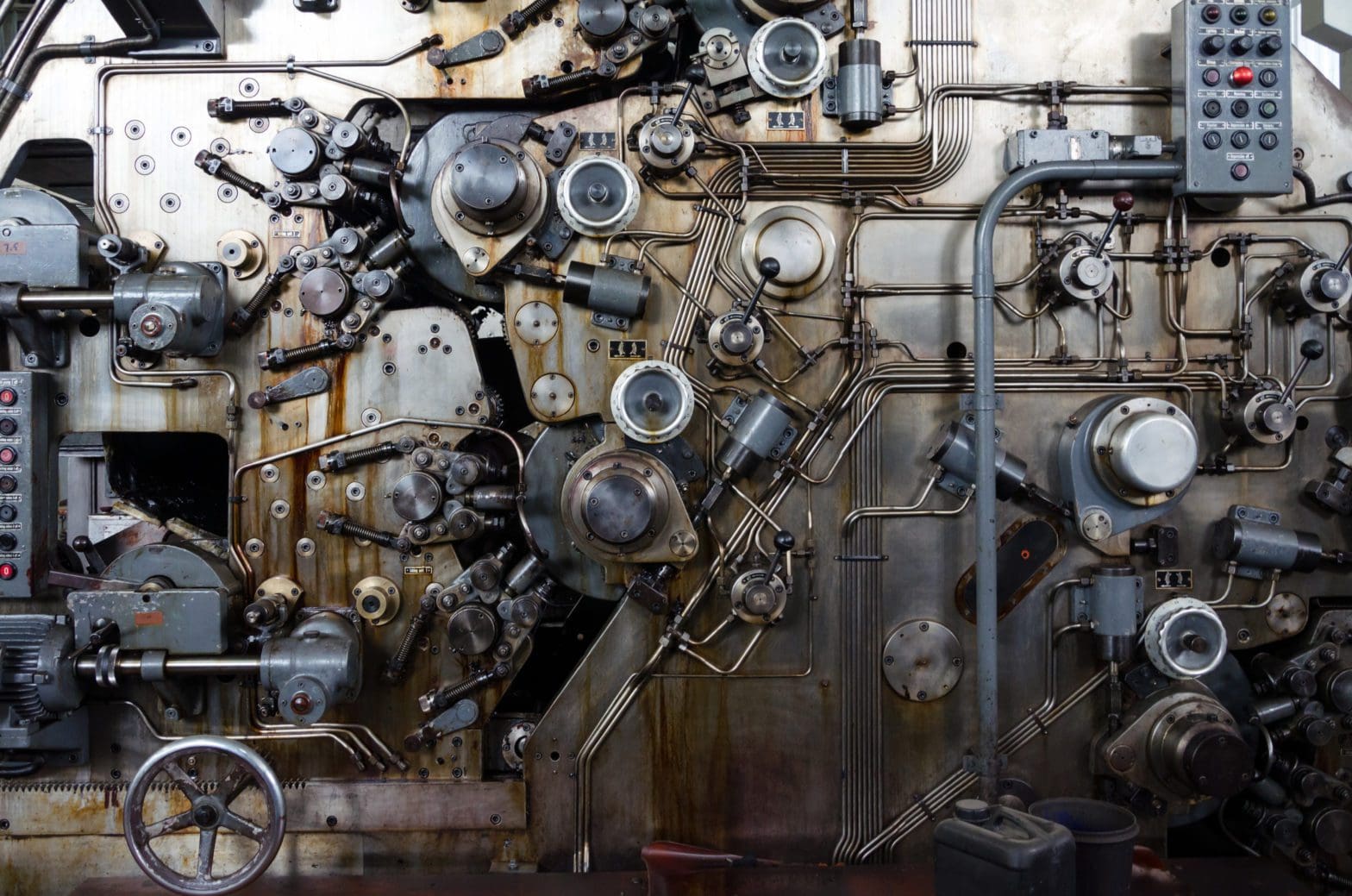

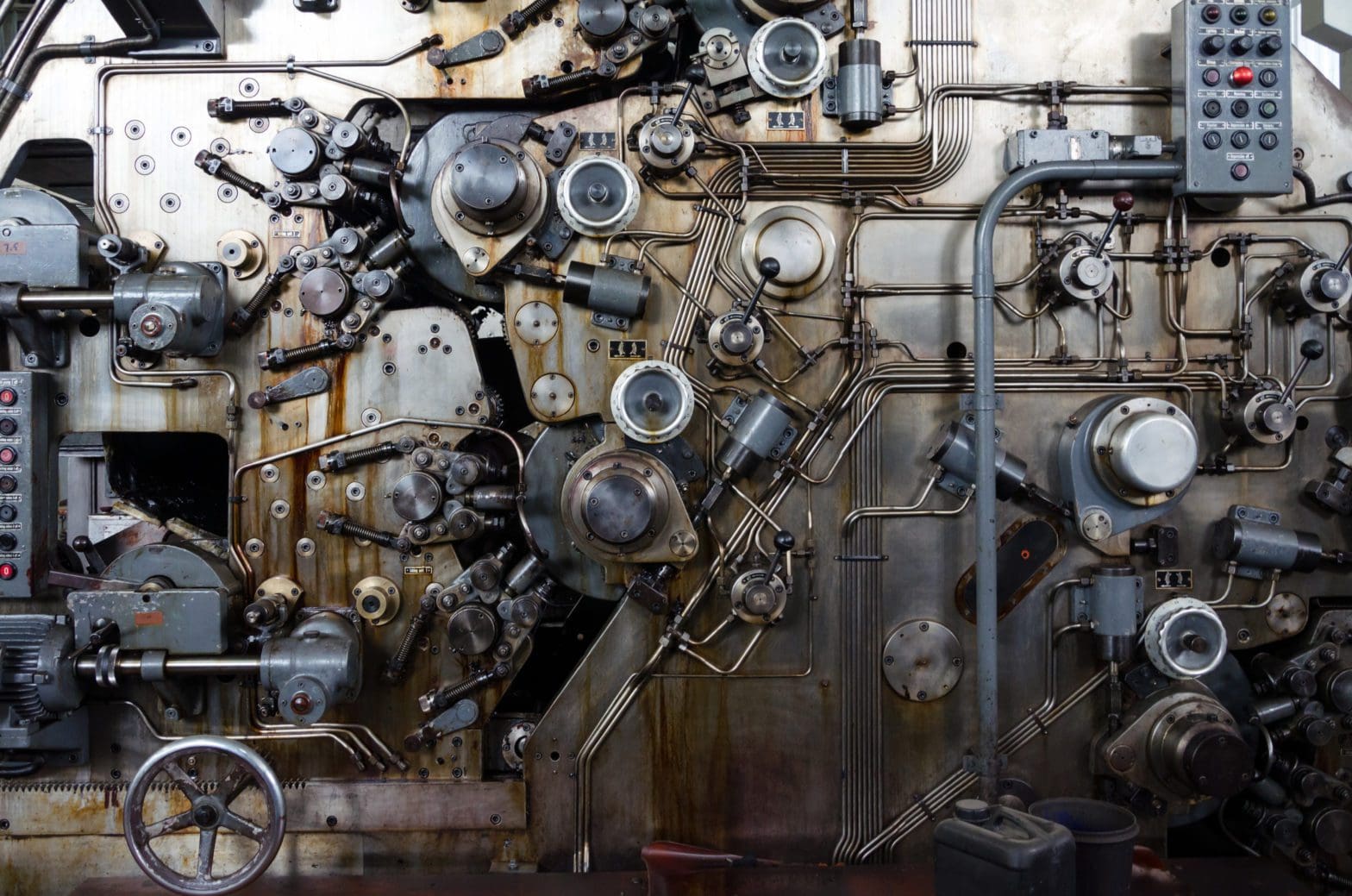

When it comes to metal repairs, cold spray technology is increasingly popular within many industries and has become common for repairs.

What Industries Use Cold Spray Technology For Repairs?

When it comes to metal repairs, cold spray technology is increasingly popular within many industries and has become common for repairs.

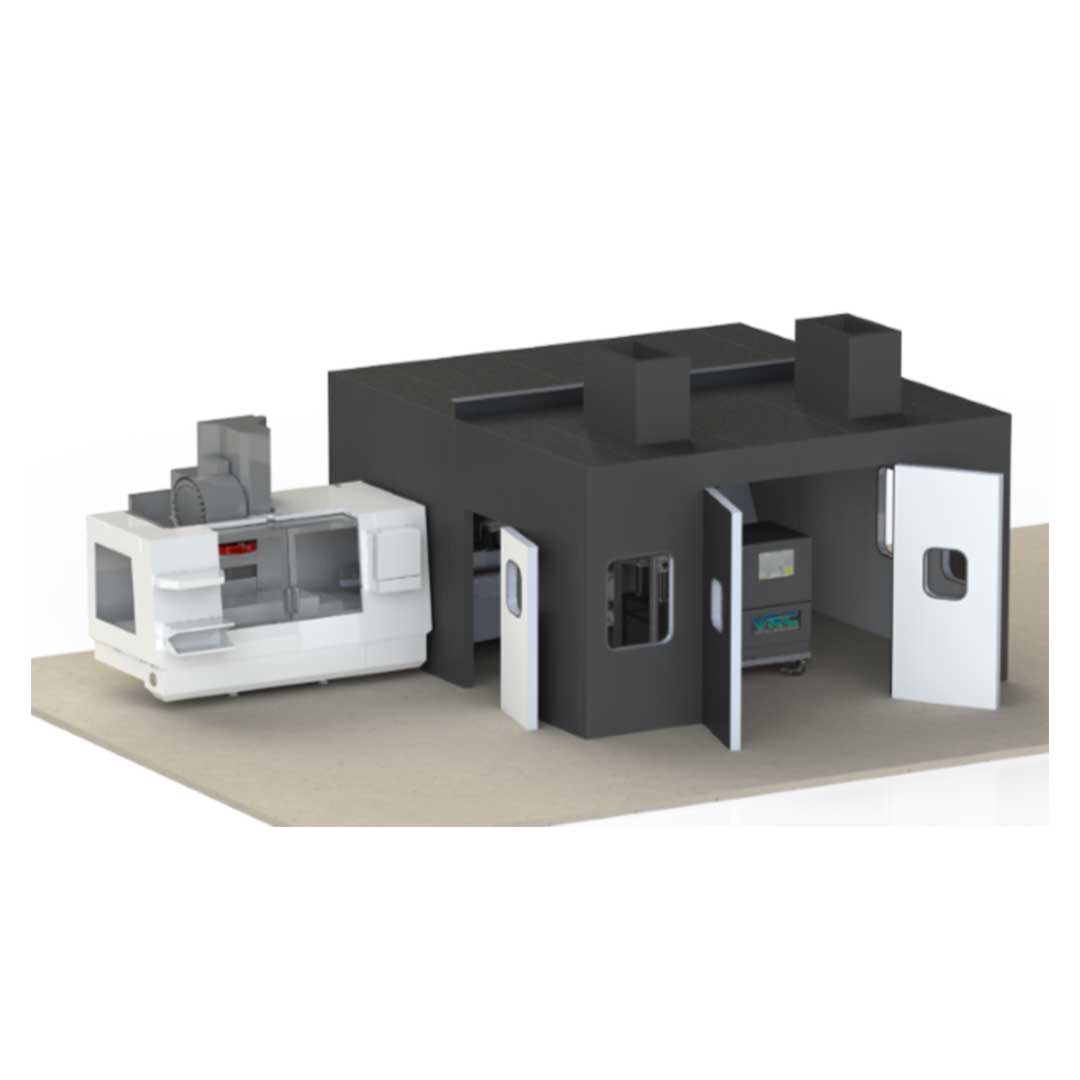

VRC Metal Systems provides custom automation solutions for cold spray and hybrid or additive manufacturing and subtractive manufacturing. Subtractive and Additive Manufacturing Process The additive manufacturing and subtractive operation combine many processes, allowing an automated subtractive operation to remove the outer layers of material from a part by using a Computer Numerical Control (CNC) Machine. New material is then… Continue reading Automated Additive And Subtractive Systems

Have you heard of cold spray and wondered how it might apply to your industry? Are you searching for an easier or faster way to make metal surface repairs? Cold spray metal repair might just be the ticket. Because of its ease and flexibility, cold spray metal repair is useful across a wide variety of… Continue reading What Is Cold Spray Used For?

If you are familiar with the thermal spray industry, then you have heard of cold spray manufacturing. Cold spray is the lowest temperature thermal spray and has the highest velocity of all the spray processes. But what makes the use of cold spray manufacturing essential? If you are starting a new project or using cold… Continue reading What Is Cold Spray?

The VRC Cold Spray Systems is an integrated solution for cold spray development up to full scale part production. The system includes everything you need to get your cold spray program started, including: A fully integrated VRC cold spray system Integrated automation Sound Dampening Enclosure [<85 dBa] Wet Dust Collector with HEPA filtration Small to… Continue reading VRC Cold Spray Systems