The use of high pressure cold spray for metal deposition has skyrocketed since the process was invented in Russia in the 1980s. Unlike conventional repair methods like welding, cold spray is a solid-state method. It does not heat the material to its melting point.

A process like this can extend operating life through reliable repairs of crucial parts, and it has earned its popularity in industries like aerospace and engine remanufacturing.

On the other hand, cold spray can’t do everything. It is not meant to replace other well-established repair methods – it is meant to expand your repair capabilities! Always take the time to consider which tools will get the job done right.

Today, come with us as we look at the cold spray coating process with an eye toward its limitations. Cold spray technology is being continually developed so many of these disadvantages may soon disappear.

What Are the Limitations of Cold Spray? The Big Difference: Cold Spray is Solid State

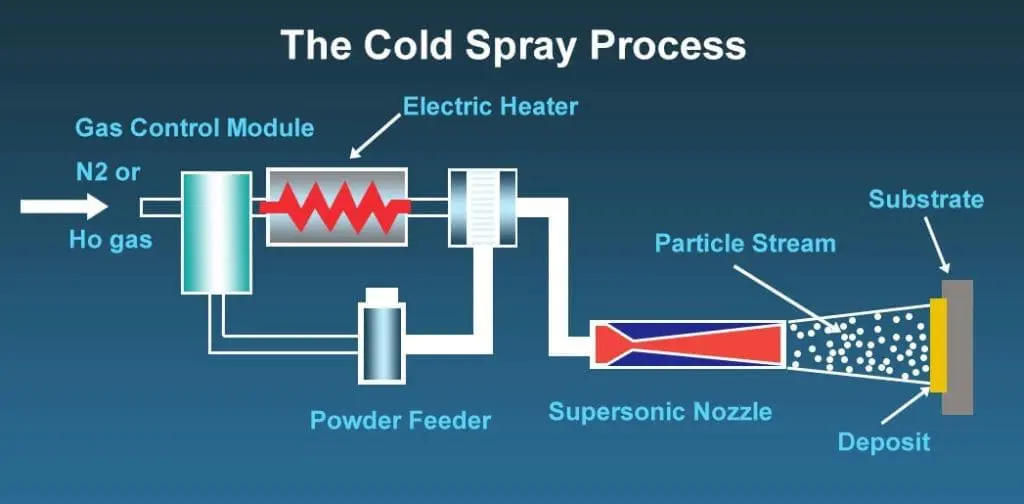

The key feature of cold spray is that there is no melting. It is a solid-state process. Feedstock in fine powder form is accelerated to supersonic speeds towards the part being repaired. The impact induces high deformations in the particles and the outermost skin (~1/1000th inch) of the part.

This disrupts the grain structures in both, but the grain structures spontaneously re-form. This promotes metallurgical bonding between the part and the deposit and within the deposit. This prevents common problems seen in thermal spray and welding, such as warping, heat-affected zones, low adhesion strength, limited cohesive strength, and tensile residual stresses.

The particles can include metals and non-metals in many ratios, making it flexible. It can apply protective and preventive coatings as well as more conventional repairs, depending on the use case.

Cold Spray Metal Deposition Limitations

The chief limitation of cold spray repair strategies comes from the loss of ductility. A ductile material can safely bend, pull, and twist without straining to its breaking point. The high deformation of the feedstock during deposition take a toll on how ductile the material is.

Depending on the application, of course, this might not present too many problems. If the material will be under a lot of stress, however, the loss of ductility could lead to an undesired fracture or distortion. Post-spray heat treatment can mitigate this where possible.

Cold spray systems also have a fairly coarse planar resolution, around three millimeters. The deposit layers are typically 0.1mm thick. If finer features are needed (say, conductive traces) then masking is required.

Cold spray systems have trouble creating sharp corners. Due to the aforementioned resolution problems, parts will develop a rounded, washed-out shape after the process. This can prove problematic in some cases, though not always.

Finally, cold sprays have trouble creating certain shapes. A cold spray system cannot currently make effective walls, for instance, nor can it currently create a proportionally tall, thin structure. Tall features require tapered bases for extra stability.

These factors limit cold spray processes to a near-net-shape final result. True net-shape work requires additional machining.

Finally, cold spray is seldom used for joining. While cold spray can bridge gaps to hold parts together there is no fusion between the parts. The unfused faces can act like a crack starter, causing the joint to fail.

Cost Factors

While cold spray often beats other methods in cost-effectiveness, it still has some costly elements to consider. Certain materials require helium process gas, which is costly and at times difficult to get, even if cost is not an object. .

Cold spray manufacturing and repair can also require a lot of replacement nozzles. Cold spray proves quite effective with hard metals, but those same metals can damage a nozzle, leading to replacement.

It does, however, allow the retrieval of most waste. Waste ends up landing as metal dust, which an operator can collect.

Comparisons With Other Repair Strategies

With those limitations in mind, we can now look at when you’d want to use cold spray or switch to another method. No manufacturing process offers perfect results in all circumstances. Cold spray has things it excels at, and other things do, too.

Comparison With Replacement Parts

Replacement parts will be perfectly at factory specifications. If you have very specific needs in terms of ductility or composition, a replacement part might suit the situation.

Then again, replacement parts can come with a high cost. A cold spray repair, conversely, takes much less of the materials.

In time-sensitive applications, cold spray can win out or lose depending on the part. Some parts can have manufacturing times measured in months, and a cold spray repair will save time and money. However, if you can purchase the part on the spot, that will be a bigger time-saver.

Comparison With Thermal Spray

As far as the cost savings go, thermal spray and cold spray offer comparable benefits. Both of them allow for repairs or finishes at a fraction of the cost of a new part.

Thermal spray processes can emit toxic gas, depending on the particles involved. This stems from the high temperatures involved. If your working environment makes this less of a concern, the “green” nature of cold spray won’t play as big a role.

Thermal spray allows the use of a wider range of materials. Anything that melts or becomes plastic can be used in the thermal spray process, whereas cold spray uses only metals, alloys, and mixtures of metal and non-metal particles.

Finally, thermal spray has a greater likelihood of damaging the parts. Heat-sensitive parts, in particular, can suffer if subjected to thermal spray processes.

In most cases, however, cold spray compares favorably to thermal.

While thermal spray performs many of the same tasks, cold spray often performs them in a safer, more reliable way with a broader set of use cases. Cold spray is also itself repairable by cold spray. In fact, there is no known limit to how many times a cold spray repair can be repeated in the same spot.

The Right Tool for the Job

Every manufacturing and repair process has its unique quirks. We’ve highlighted some of cold spray’s here.

If you really need a precise edge and can’t machine the part, it won’t work out. If you need a fine resolution, you might have a tough time.

Still, this represents the state of cold spray metal deposition technology right now, in the early 2020s. The future of the technology is bright.

Are you looking for more detailed information on cold spray? Are you interested in one of our products? Get in contact with us today.