Have you heard of cold spray and wondered how it might apply to your industry? Are you searching for an easier or faster way to make metal surface repairs? Cold spray metal repair might just be the ticket.

Because of its ease and flexibility, cold spray metal repair is useful across a wide variety of industries. If you have been wondering how cold spray might apply to your business needs, look no further. VRC Metal Systems is a leader in cold spray technology. This article will outline an array of cold spray applications.

A quick summary of cold spray:

Despite its name, cold spray is technically in the family of thermally sprayed metal powders.

However it is a solid-state process using much lower process gas temperatures than melt-based processes, which is why it’s called “cold”. The process gas temperatures are kept lower than the feedstock melting temperatures, and the process relies on high kinetic energy for deposition:. Metal particles are deposited at a high (supersonic) velocity onto your desired surface, resulting in extreme deformation of the feedstock particles and the outermost layer (100 micron or less) of the substrate. This mutual deformation disrupts the grain structures in both the particles and the substrate. Those grain structures spontaneously re-form, promoting a strong metallurgical bond between both. This process also continues within the deposit as it forms, enabling high cohesive strength as well.

Some advantages of cold spray metal repair include:

- Low-temperature processing means no heat-affected zones

- Compressive residual stresses, which help prevent crack formation and growth.

- Initial particles retain original alloying structure

- Very little oxidation

- Extremely durable coating structure

- Coatings can be made to virtually any thickness, from 100 micron to several inches.

- Reduced cooling requirement because of low-temperature process

- Low-waste process in which there is little-to-no discard material

- Cold spray can itself be repaired with cold spray

- There is no known limit to the number of repair cycles

- Unusual or otherwise difficult material pairings can be created.

What industries benefit from using cold spray metal repair?

Cold spray technology offers so much flexibility. Typically, industries that utilize cold spray metal repair often operate under harsh conditions and require reliable, economical repairs. Of course, speedy repairs are also a priority for these demanding industries.

Aerospace, shipping, oil, gas, and manufacturing industries all utilize cold spray technology.

These industries have relied on thermal spraying processes over the past few decades. More recently, they have begun to recognize the benefits of cold spray metal repair. As it continues to grow in popularity, new uses and innovations are emerging.

Let’s explore how each of these industries uses cold spray for metal repair.

The aerospace industry spends billions on repairs.

When a part begins to show signs of aging, the aerospace industry faces a pricey dilemma. They must replace the components or pay for the costly repairs. Historically, aerospace manufacturers have chosen to repair the part if the total repair cost is less than 80% of a new component.

Cold spray metal repair is reshaping the aerospace industry.

As a budget-friendly yet extremely reliable innovation, cold spray has changed the expectations of aircraft manufacturers and maintenance facilities. Cold spray metal repair can be utilized on relatively small metal components or applied to a larger area to repair corrosion and build material thickness.

The shipping industry utilizes cold spray to ensure smooth sailing and timely delivery.

As aging vessels are pushed to extreme lengths, the shipping industry needs all the help it can get to stay afloat. Cold spray metal repair can transform an old component almost new again. Cold spray metal repair not only enhances routine maintenance but also extends the life of aging vessel components.

Cold spray metal repair helps the oil industry avoid disaster.

Because there are no flames or molten metals, cold spray is one of the safest ways to repair oil and gas pipelines. The United States has over 2 million miles of pipeline infrastructure, and it isn’t getting any younger. These pipelines require constant monitoring, maintenance, and repair to avoid environmental and hazardous disasters. Cold spray metal repair is an innovative solution that can quickly and easily patch pipelines in-situ.

How is cold spray metal repair used in manufacturing settings?

Unlike its other common uses, cold spray technology has recently become an additive manufacturing solution. With precise application, cold spray can create near-net-shape components – almost like 3D printing with metal.

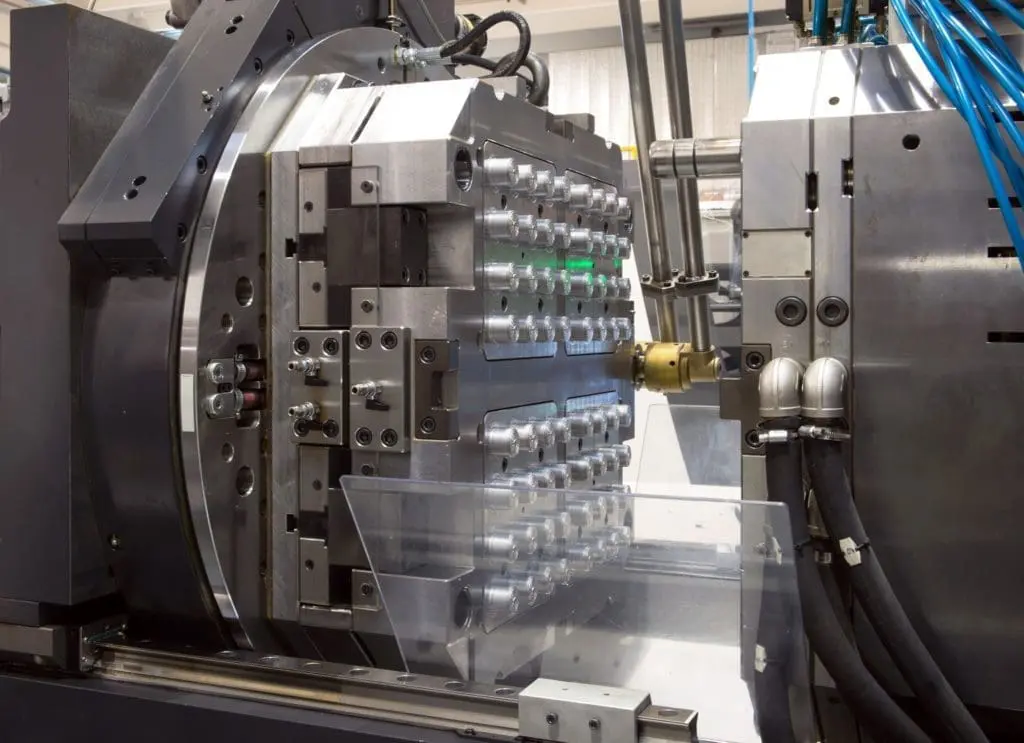

Cold Spray is also highly applicable for injection mold repair.

Injection molding tools are notoriously expensive. With one wrong cut or scratch, the mold can be rendered useless. Cold spray presents a new, durable solution for fixing mold imperfections on-site, saving manufacturers valuable time and money.

The cold spray metal repair process works with a variety of material types.

As you can imagine, repairs and maintenance across these industries require many different metallic and semi-metallic materials. Luckily, cold spray metal repair is very flexible when it comes to particle type.

What kind of materials can you deposit with cold spray technology?

Cold spray deposits powdered materials at extremely high speeds to create a durable surface. These powder particles can be pure metals, metal alloys, or a mixture of metallic and non-metallic particles. Such combinations can be used to confer wear resistance to parts.

How do you choose the right material for repairs?

It depends on your job’s specific requirements. Typically, you will want to repair a surface with very similar or enhanced materials. You can stick to basic materials that match the substrate on which you’re spraying or opt for enhancements to create a protective coating for your part.

When and where might you want to apply cold spray as a protective coating?

Cold spray can be applied as a custom coating to cover and protect your parts from wear. For example, cold spray metal repair is especially useful to prevent corrosion in marine environments. You can enhance the coating with bronze, stainless steel, zinc, aluminum, or even tantalum to avoid wear and extend the life of your components.

To summarize, cold spray is a flexible solution that will save you time and money.

Cold spray solutions from VRC Metal Systems work around the clock to keep these industries moving. As we continue to grow, we hope you reach out to explore the possibilities of cold spray for your business.

We’ve outlined just a few examples of cold spray metal repair in this article, but there are so many more to discover. If you have any questions or ideas about how cold spray might be useful for your business, reach out to us. We are ready to help you discover a world of possibilities with cold spray metal repair.